Top Strategies for Sourcing Xanthan Gum: Unlocking Global Procurement Success

Table of Contents

- Challenges in Sourcing Xanthan Gum: Identifying Key Issues

- Understanding Quality Standards and Regulations in Xanthan Gum Procurement

- Evaluating Suppliers: Essential Criteria for Reliable Partnerships

- Navigating Price Fluctuations in the Xanthan Gum Market

- Leveraging Technology for Efficient Xanthan Gum Sourcing

- Building Resilient Supply Chains for Xanthan Gum Acquisition

- Exploring Cationic Polyacrylamide: Benefits, Applications, and Best Practices for Optimal Use

- FAQS

- Conclusion

- Related Posts

When you look at the food and industrial world these days, it’s clear that Xanthan Gum has really become an essential ingredient. It’s loved for its ability to thicken and stabilize, making it a go-to for many manufacturers. The global market for Xanthan Gum is expected to hit around $1.14 billion by 2025, with an annual growth rate of about 5.8%. That’s mainly because of the rising demand in the food and drink scene—especially in gluten-free products—and its role as a stabilizer. Companies like QINGDAO OUBO CHEMICAL CO., LTD, which was started in 2011, know just how important it is to have solid sourcing strategies to keep up with the ever-changing market and what consumers want. If you want to stay competitive nowadays, it’s pretty much essential to find reliable suppliers and streamline your purchasing process. By focusing on these key strategies and making the most of global supply networks, businesses can really boost their ability to get high-quality Xanthan Gum, all while keeping costs in check. It’s all about working smarter in a pretty fast-paced industry, right?

Challenges in Sourcing Xanthan Gum: Identifying Key Issues

Finding and buying xanthan gum isn’t exactly a walk in the park — there are a bunch of hurdles that can really throw a wrench in your plans. One big headache is how supply chains can be all over the place, often caused by unpredictable stuff like politics or natural disasters. These hiccups can make prices jump around and stocks harder to get, so it’s pretty important to stay flexible and have backup plans when sourcing.

**Tip 1:** Build solid relationships with a bunch of suppliers. Spreading your supplier contacts around helps lessen the risk of shortages or delays. Plus, working with suppliers from different parts of the world can give you access to better quality xanthan gum at reasonable prices — don’t just stick to one region!

Another big challenge is making sure the quality stays consistent. Since xanthan gum is used in everything from food to pharma, any weird deviations in quality can cause serious issues. That’s why it’s super important to have strict testing and certification in place, so you know you’re getting reliable products that meet industry standards.

**Tip 2:** Do regular audits and quality checks. Keeping close tabs on your suppliers and agreeing on clear quality standards helps keep things steady. And don’t forget — keeping an eye on changing regulations can save you from compliance headaches down the line. Staying on top of these things makes your sourcing more reliable and less stressful.

Understanding Quality Standards and Regulations in Xanthan Gum Procurement

In the fast-moving world of food and pharma, sourcing xanthan gum has really become a big deal, especially with demand growing worldwide. If you’re in the biz, understanding the quality standards and rules around buying xanthan gum is super important — it’s all about staying compliant and making sure you can succeed in the market. According to recent industry reports, like the latest from IMARC Group, the global market for xanthan gum’s poised for some serious growth. That’s mainly because it’s used in so many areas — from food and cosmetics to biopharmaceuticals, you name it.

When it comes to getting your xanthan gum, your sourcing strategies need to stay up-to-date with international quality standards, especially those set by regulators. For example, the Codex Alimentarius has strict guidelines that focus on purity and safety — ignoring those isn’t an option. Plus, getting certifications like ISO 9001 can really boost your credibility as a supplier. It’s also crucial for companies to have solid quality checks in place to make sure what they buy actually meets these standards. Skipping this step can lead to costly recalls and hurt your brand’s reputation, big time. And these days, there’s also a growing emphasis on sourcing sustainably. Customers want to know that the products they buy are made transparently and responsibly — so suppliers need to be able to show that their production processes are up to scratch, too.

Evaluating Suppliers: Essential Criteria for Reliable Partnerships

When you're on the lookout for suppliers to source xanthan gum—something that's pretty much everywhere, from our favorite snacks to pharmaceuticals and industrial uses—you're really gotta do your homework. Starting with their experience and expertise is key. Think of it like dating—companies with a solid track record are more likely to stick to their promises and deliver quality stuff, pretty much consistently.

And honestly, taking some time to read customer reviews or case studies can give you a good feel for how reliable they are and how they handle their clients. It’s like getting the inside scoop.

Also, don't forget to check out their certifications and whether they follow industry standards. Making sure they meet quality management systems like ISO 9001 and have food safety certifications like FSSC 22000 really helps cut down the risks—nobody wants issues with product safety or quality, right? Plus, you’ll want to get a sense of their production capacity and how quickly they can respond to changing demands.

A supplier that can ramp up quickly but still keep quality in check is a real win—especially when your supply chain depends on it and market needs can change overnight.

Navigating Price Fluctuations in the Xanthan Gum Market

Dealing with the ups and downs in the xanthan gum market has really become a must for companies trying to keep up with global sourcing. As more and more industries start to rely on this versatile thickener, understanding how the market moves is more important than ever. I’ve seen reports saying that the xanthan gum market is set to take off—going from around $400 million in 2025 to a staggering $1.9 billion by 2032. That kind of growth is pretty wild, and it just shows why having smart sourcing strategies is so crucial to avoid getting caught out by price swings.

**Tip 1:** Think about locking in prices by signing long-term deals with your suppliers—that way, you won’t be as exposed to sudden market shifts. Also, spreading your supply sources around can really give you more power when it comes to negotiating prices.

As things keep changing in the market, it’s super important to stay in the loop about global supply chain news and how it might affect costs. Being able to anticipate these changes and adapt quickly can give your business a serious edge. For example, recent data shows that the global market for info navigation and remote sensing is expected to hit about $3.28 billion by 2024, which hints at a growing link between these tech fields and procurement strategies.

**Tip 2:** Make use of market intelligence tools that can help you predict price trends and tweak your purchasing plans on the fly. Chatting with industry experts can also be a huge help—they often have insider info on upcoming shifts that could impact xanthan gum prices.

Top Strategies for Sourcing Xanthan Gum: Unlocking Global Procurement Success

| Region | Average Price (USD/kg) | Supply Availability | Market Trends | Key Factors Influencing Prices |

|---|---|---|---|---|

| North America | $3.50 | Stable | Increasing demand in food industry | Raw material costs, production capabilities |

| Europe | $3.80 | Moderate | Regulatory changes affecting imports | Supply chain disruptions, climate variability |

| Asia | $2.90 | High | Export dynamics shifting | Labor costs, transportation rates |

| South America | $3.30 | Low | Emerging market opportunities | Economic stability, import tariffs |

| Africa | $3.60 | Varies by country | Potential for growth but challenges remain | Infrastructural issues, local regulations |

Leveraging Technology for Efficient Xanthan Gum Sourcing

Getting the hang of sourcing xanthan gum efficiently isn’t just about following traditional methods anymore. Companies are now leveraging cutting-edge tech and fresh approaches that seriously shake up how procurement works. For instance, by tapping into data analytics and AI, businesses can better optimize their supply chains, cut down costs, and stay ahead of the game. Recently, industry insiders have been stressing the importance of using eco-friendly resources—like food and agro-industrial waste—as alternative sources for producing xanthan gum. Not only does this tick the boxes for sustainability, but it also helps improve the purity and effectiveness of the final product.

Pro tip: Make sure to use tech platforms that offer real-time market insights and forecasts. These tools can give you the edge, helping you stay on top of price swings and supply hiccups without breaking a sweat. Having streamlined digital procurement systems in place makes a huge difference in making quick, informed decisions and adjusting your sourcing strategy on the fly.

On another note, the applications of xanthan gum are expanding fast across different sectors. Research shows it’s great for improving food textures and even works as an effective barrier in edible coatings. For example, spray technology with xanthan gum-based coatings can really boost shelf life while keeping food fresh longer.

Another tip? Investing time in R&D to find new and exciting ways to use xanthan gum can give you a real edge over the competition. Collaborating with universities or research centers can also spark innovation and help develop smarter sourcing techniques—and honestly, those partnerships can be pretty rewarding.

Building Resilient Supply Chains for Xanthan Gum Acquisition

In today’s unpredictable market, making sure your supply chains for xanthan gum are resilient is more important than ever. I came across a report by Grand View Research that said the global xanthan gum market was worth around USD 1.14 billion back in 2022. And get this—it's projected to grow at an average rate of about 5.5% every year from 2023 until 2030. That kind of growth just shows how vital it is for companies to build strong, flexible sourcing strategies. You never know when things like raw material shortages, political tensions, or logistical hiccups might throw a wrench in the works.

So, what’s the best way to build resilience? Well, a good starting point is diversifying your suppliers and thinking about sourcing regionally. I read a study by Deloitte that found companies with multiple suppliers are actually 50% more likely to hit their supply chain goals compared to those relying on just one. Also, embracing tech solutions like blockchain for better traceability and real-time tracking can seriously boost transparency and efficiency. In the end, as demand for xanthan gum keeps climbing across different industries, investing in a sturdy, adaptable supply chain isn’t just smart — it’s pretty much essential if you wanna stay ahead of the game.

Exploring Cationic Polyacrylamide: Benefits, Applications, and Best Practices for Optimal Use

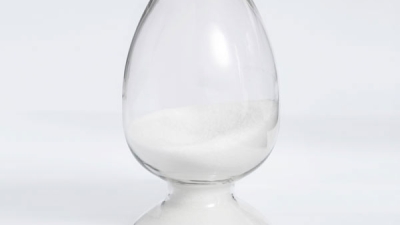

Cationic polyacrylamide, a white granule with a linear high molecular structure, has gained attention in various industries due to its unique properties. As a water-soluble polymer, it offers a range of benefits, including its non-toxic and odorless nature. This makes it an excellent choice for applications in water treatment, where safety and efficacy are paramount. Its ability to absorb moisture effectively enhances its functionality, allowing it to interact with various materials and aid in sedimentation processes.

The positive charge active groups present in cationic polyacrylamide's molecular chains play a crucial role in its performance. These groups facilitate interactions with negatively charged particles, promoting flocculation and enhancing the clarity of water. Additionally, its insolubility in organic solvents like ethanol and acetone ensures that it remains stable in various environmental conditions. To maximize its benefits, it's essential to follow best practices in its application, including proper dosing and thorough mixing, ensuring optimal results in water purification and other industrial processes.

FAQS

: The primary challenges include supply chain volatility due to geopolitical factors and natural disasters, which can affect pricing and availability.

Buyers can mitigate risks by establishing strong relationships with multiple suppliers and diversifying their supplier base.

Quality control is crucial because xanthan gum is used in food and pharmaceuticals, and inconsistencies in quality can lead to serious issues.

Implementing regular audits, quality assessments, and collaborating with suppliers on quality benchmarks are essential for maintaining consistent quality.

It is important to consider the supplier's experience, certifications, compliance with industry standards, production capacity, and customer testimonials when evaluating suppliers.

Suppliers should adhere to quality management systems like ISO 9001 and possess food safety certifications such as FSSC 22000 to ensure quality and safety.

Staying updated on regulatory changes can assist buyers in navigating compliance issues more effectively, ensuring that their sourcing practices meet industry standards.

Evaluating a supplier's production capacity is vital to ensure they can scale operations quickly to meet demand fluctuations while maintaining quality.

Conclusion

When it comes to finding the right sourcing strategies for xanthan gum, companies often run into a bunch of challenges—like unpredictable market prices and strict quality standards. It’s pretty clear that understanding the key regulations and pinpointing the main issues in the procurement process are essential steps if you want to secure reliable suppliers. Taking the time to evaluate potential partners based on clear, established criteria can really help build solid, trustworthy relationships—making sure you get high-quality xanthan gum consistently.

Using technology can be a game-changer, making sourcing operations much more efficient and helping organizations better handle the twists and turns of the market. Plus, building a resilient supply chain is crucial—it helps mitigate risks and makes it easier to adapt when conditions change. For companies like Qingdao Oubo Chemical Co., Ltd., which deal with all kinds of polyacrylamide products, adopting these strategies isn’t just a good idea; it’s pretty much a necessity to successfully source xanthan gum, satisfy client demands, and stay ahead of the competition.

Related Posts

-

Market Trends and Forecast for Best Polyacrylamide Emulsion by 2025

-

How to Maximize After Sales Support and Minimize Maintenance Costs for Best Apam Anionic Polyacrylamide

-

Ultimate Checklist for Evaluating Water Treatment Coagulant Prices in Your Industry

-

Unlocking the Future of Water Treatment with Best Flocculant Anionic Nonionic Polyacrylamide Trends for 2025

-

5 Best Applications for Acrylamide Resin in Modern Industries

-

Choosing the Right Manufacturer for Best High Molecular Weight Anionic Polyacrylamide with Industry Insights

Blog Tags:

Ava

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Jessy Lin

Paul Zhou:8613356391894 Eric Wong:8615963245439Emily Wu:8617866856171

-

WeChat

Paul Zhou

-

WeChat

Eric Wong

-

WeChat

Emily Wu