Ultimate Guide to Using Polyacrylamide in Water Treatment Processes

Table of Contents

- Overview of Polyacrylamide and Its Role in Water Treatment

- Types of Polyacrylamide: An In-Depth Look at Their Properties

- Applications of Polyacrylamide in Various Water Treatment Processes

- Benefits of Using Polyacrylamide in Water Treatment Systems

- Safety and Environmental Considerations When Using Polyacrylamide

- Best Practices for Polyacrylamide Application in Water Treatment

- Insights from Industry Reports: The Growing Demand for Cationic Polyacrylamide in Water Treatment and Beyond

- FAQS

- Conclusion

- Related Posts

When it comes to water treatment, Polyacrylamide, or PAM for short, has really been catching people's attention lately. It’s known for being pretty effective across a bunch of different processes. If you’ve been following industry trends, you’ve probably seen reports suggesting that the global demand for cationic, anionic, and nonionic PAM is only going up—mainly because companies are looking for better, more advanced water treatment options. A company like QINGDAO OUBO CHEMICAL CO., LTD, which’s been around since 2011, has made a name for itself by offering a pretty wide variety of PAM products designed specifically for water treatment. Using PAM for things like flocculation, sedimentation, and sludge dewatering has really boosted efficiency in these processes. As standards for water quality get stricter and environmental rules tighten up, knowing how to best use PAM is super important for industries that want to stay sustainable and compliant—but still get the job done effectively.

Overview of Polyacrylamide and Its Role in Water Treatment

Polyacrylamide, or PAM for short, is this water-soluble polymer that’s pretty well-known for playing a key role in different water treatment processes. Basically, it acts like a flocculant—helping tiny suspended solids clump together, which makes sedimentation and filtration a whole lot more efficient at treatment plants. I read somewhere that, according to MarketsandMarkets, the global market for polyacrylamide in water treatment is expected to hit around $5.7 billion by 2025. Most of that growth is driven by the rising demand for clean water in different industries—crazy how much water treatment is evolving, huh?

In real-world use, PAM has shown it can really do the job—from municipal wastewater cleanup and industrial water management to even helping out in the oil and gas game, especially during hydraulic fracturing. One of the coolest things is how it can cut down water turbidity—meaning, it makes water clearer and reduces the amount of chemicals needed. I came across a study in the Journal of Water Process Engineering that said using polyacrylamide can lower suspended solids by over 90% in some wastewater scenarios. That’s pretty impressive, right? It shows how effective PAM can be for improving water quality while tying into more eco-friendly practices. By making treatment processes more efficient, PAM helps companies stay compliant with regulations and also supports protecting our environment—that's a win-win in my book.

Types of Polyacrylamide: An In-Depth Look at Their Properties

Polyacrylamide, or PAM for short, is a synthetic polymer that comes in a bunch of different forms, each designed for specific water treatment tasks. The most common types are non-ionic, anionic, and cationic, and they each have unique properties that make them suitable for different applications.

For example, non-ionic PAM is really good at helping with flocculation and sedimentation — it’s often used in municipal waste treatment plants. Its neutral charge means it's compatible with a wide variety of sediments and pollutants, which helps with removal during treatment.

On the flip side, anionic PAM has a negative charge and works especially well in high-solids scenarios, like mining or mineral processing. It helps particles coagulate, which makes the water clearer by letting solids settle out faster. Then there's cationic PAM, which has a positive charge — it’s fantastic for dealing with organic contaminants. It’s often used in industrial effluent treatment because it bonds well with negatively charged particles, boosting the formation of larger flocs.

Getting to know these different types is super helpful for water treatment pros because it helps them pick the right polymer for the job. When the right PAM is used, the whole process becomes a lot more efficient and effective.

Applications of Polyacrylamide in Various Water Treatment Processes

Polyacrylamide, or PAM for short, is pretty well-known for how effective it is in all kinds of water treatment processes. Basically, this synthetic polymer helps make things like

sedimentation,

clarification, and

filtration way more efficient.

In city water treatment plants, you'll often find PAM being used as a flocculant—it helps all those tiny particles clump together into bigger chunks, which are much easier to remove. That means

clearer water and less strain on the filters, so everything runs smoother and faster.

On the industrial side of things—think mining or wastewater treatment—PAM is a total lifesaver. It helps get rid of heavy metals and organic pollutants, so the water that gets dumped back into the environment is much cleaner. Plus, PAM is pretty versatile; you can tweak it to fit different pH levels or temperatures, depending on what you need.

As companies and industries are looking more into sustainable practices, using polyacrylamide in water treatment definitely seems like a smart move—good for meeting regulations and helping out the environment at the same time.

Benefits of Using Polyacrylamide in Water Treatment Systems

Polyacrylamide, or PAM for short, has really become a go-to in water treatment these days. It’s got a bunch of advantages, especially when it comes to making wastewater management more efficient. You can find different types—cationic, anionic, and nonionic—which all help improve how flocculation and sedimentation work. These steps are super important for getting rid of suspended solids and contaminants from water. The cool thing is, PAM is pretty versatile, so it’s a reliable choice for industries that need solid water treatment solutions.

Here at Qingdao Oubo Chemical Co., Ltd., we’ve been in the game since 2011, and we pride ourselves on providing top-notch polyacrylamide products designed to tackle all kinds of water treatment challenges. Using PAM can lead to clearer water, lower chemical costs, and more sustainable operations overall. Whether it’s municipal wastewater or industrial needs, our range of cationic, anionic, and nonionic options is built to deliver optimal performance and help protect our water resources — basically, we’re here to keep things running smoothly and safely.

Safety and Environmental Considerations When Using Polyacrylamide

Whenever you're working with polyacrylamide in water treatment, it's really important to keep safety and the environment in mind. From what I've read, this polymer can actually help with flocculation and sedimentation, which means it can really boost water quality. That said, handling it isn’t just a walk in the park—you’ve got to follow strict safety rules to avoid risks like inhaling it or getting it on your skin. Prolonged exposure, apparently, could be risky health-wise, so anyone working with it should definitely wear personal protective gear—trust me, it’s worth it!

A good tip is to always do a quick risk check before using polyacrylamide in big projects. And don’t forget to have the Material Safety Data Sheets (or MSDS) handy—they contain all the info you might need on safe handling and what to do in emergencies.

On the environmental side, it’s a bit of a balancing act. Polyacrylamide is super effective and popular, but some formulations don’t break down easily in water, which could hurt aquatic life. So, it’s really responsible to follow proper disposal and treatment procedures to keep ecosystems safe.

My advice? Regularly check the environmental impact of your treatments, and if you can, look into more eco-friendly, biodegradable options. That way, you’re not just cleaning water—you’re also helping protect the planet.

Best Practices for Polyacrylamide Application in Water Treatment

Polyacrylamide, or PAM for short, is this pretty handy synthetic polymer that's been catching on in water treatment circles lately. People love it because it helps out with sedimentation, filtration, and sludge dewatering—that’s a game-changer. If facilities use it the right way, they can really boost how well it works while also keeping things eco-friendly. The Water Environment Federation points out that using the correct amount of PAM can bump up particle removal by as much as 30%. Pretty impressive, right? It really makes a noticeable difference when it comes to water clarity and quality.

Polyacrylamide, or PAM for short, is this pretty handy synthetic polymer that's been catching on in water treatment circles lately. People love it because it helps out with sedimentation, filtration, and sludge dewatering—that’s a game-changer. If facilities use it the right way, they can really boost how well it works while also keeping things eco-friendly. The Water Environment Federation points out that using the correct amount of PAM can bump up particle removal by as much as 30%. Pretty impressive, right? It really makes a noticeable difference when it comes to water clarity and quality.

When you're choosing the right PAM for your specific needs, it’s important to think about its molecular weight and charge. For example, if you're dealing with wastewater and want to make flocs that settle fast, high molecular weight PAM works best because it forms bigger clumps. On the other hand, if you need to lower viscosity, then the lower molecular weight option could do the trick.

Quick tip: Always run a jar test first before going full blast—this helps you figure out the perfect PAM concentration and check if it gels well with your existing setup.

Timing is also everything. Adding the PAM at just the right moment can significantly boost how effective the treatment is. Industry research shows that introducing it right before sedimentation can improve efficiency by about 25%. Not too shabby!

Another tip: Keep an eye on your system regularly, and don’t hesitate to tweak the PAM dosage based on how the influent varies. That way, you keep performance steady without any surprises.

Insights from Industry Reports: The Growing Demand for Cationic Polyacrylamide in Water Treatment and Beyond

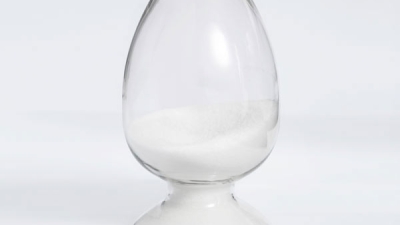

Cationic polyacrylamide, a white granule composed of a linear high molecular compound, is emerging as a pivotal player in water treatment solutions. Its unique properties, including water solubility, non-toxicity, and the presence of positively charged active groups, make it ideal for various applications, especially in the treatment of wastewater. As industries increasingly seek sustainable and efficient methods for water purification, the demand for cationic polyacrylamide is rapidly growing.

Not only is cationic polyacrylamide effective in coagulation and flocculation processes, but its ability to easily absorb moisture enhances its performance in retention and clarification tasks. It stands out in scenarios where rapid sedimentation and improved water quality are crucial. As it is insoluble in organic solvents like ethanol and acetone, cationic polyacrylamide showcases compatibility across diverse environments, thereby expanding its usability beyond traditional water treatment applications. This versatility highlights its potential in sectors including textiles, mining, and even pharmaceuticals, where efficient water and sludge management is essential for operational success.

FAQS

: Polyacrylamide (PAM) is a water-soluble polymer that serves primarily as a flocculant in water treatment processes. It helps in agglomerating suspended solids, improving sedimentation and filtration efficiency in treatment facilities.

The global polyacrylamide market for water treatment is expected to reach $5.7 billion by 2025, driven by the increasing demand for clean water across various industries.

The common types of polyacrylamide are non-ionic, anionic, and cationic. Each type has distinct properties: non-ionic is suitable for municipal wastewater, anionic is effective in high-solids applications like mining, and cationic excels in treating organic contaminants.

Studies have shown that polyacrylamide can decrease suspended solids by over 90% in certain wastewater applications, significantly improving water quality.

Best practices include proper dosage, conducting jar tests to determine optimal PAM concentration, and timing the addition of PAM at the appropriate stage of treatment to maximize effectiveness.

Regular monitoring and adjusting of PAM dosage based on fluctuations in influent quality are crucial for maintaining consistent water treatment performance and enhancing particle removal rates.

High molecular weight PAM is preferred for flocculation in wastewater treatment as it creates larger flocs that settle quickly, whereas low molecular weight PAM is effective for viscosity reduction.

Introducing PAM just before the sedimentation phase can enhance sedimentation efficiency by up to 25%, demonstrating the importance of timing in its application.

Yes, by optimizing water treatment processes and reducing chemical usage, polyacrylamide supports sustainable practices and helps meet regulatory compliance in environmental conservation.

Polyacrylamide is also used in industrial effluent management and in the oil and gas sectors for hydraulic fracturing fluids.

Conclusion

Polyacrylamide, or PAM for short, is pretty important when it comes to water treatment. It helps make these purification processes way more efficient. If you're unfamiliar, this guide gives you the lowdown on PAM — you know, the types like cationic, anionic, and nonionic — and explains what makes each of them suited for different jobs. Using PAM can really improve things like settling out solids, clarifying water, and making flocs—those clumps of dirt—more effectively, so you end up with cleaner water and better overall treatment systems.

That said, it’s also super important to keep in mind safety and environmental stuff when using PAM. Being responsible helps avoid any mishaps or negative impacts. We’ll also go over some best practices—really, how to add PAM into your setup the right way. Oh, and by the way, Qingdao Oubo Chemical Co., Ltd., has been around since 2011, and they specialize in supplying different kinds of polyacrylamide — which are key ingredients for effective water treatment solutions.

Hopefully, this gives you a clearer, more friendly intro to PAM and how it helps in cleaning up our water!

Related Posts

-

Choosing the Right Manufacturer for Best High Molecular Weight Anionic Polyacrylamide with Industry Insights

-

Top Strategies for Sourcing Xanthan Gum: Unlocking Global Procurement Success

-

10 Reasons Why High Impact Polymer is the Future of Durable Materials

-

Ultimate Guide to Understanding Polymer Anionic Polyacrylamide Msds for Global Buyers

-

The Future of High Molecular Weight Polyacrylamide: Innovations Shaping Our Industry

-

Exploring How Water Blocking Agents Enhance Durability and Longevity in Construction Applications

Blog Tags:

Sophia

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Jessy Lin

Paul Zhou:8613356391894 Eric Wong:8615963245439Emily Wu:8617866856171

-

WeChat

Paul Zhou

-

WeChat

Eric Wong

-

WeChat

Emily Wu