With the rapid development of science and the vigorous rise of industry, agriculture and manufacturing, the utilization rate of water resources is constantly looking for new directions. The most critical development direction is to use water resources reasonably, improve the utilization rate of water resources and reduce the waste of water resources.

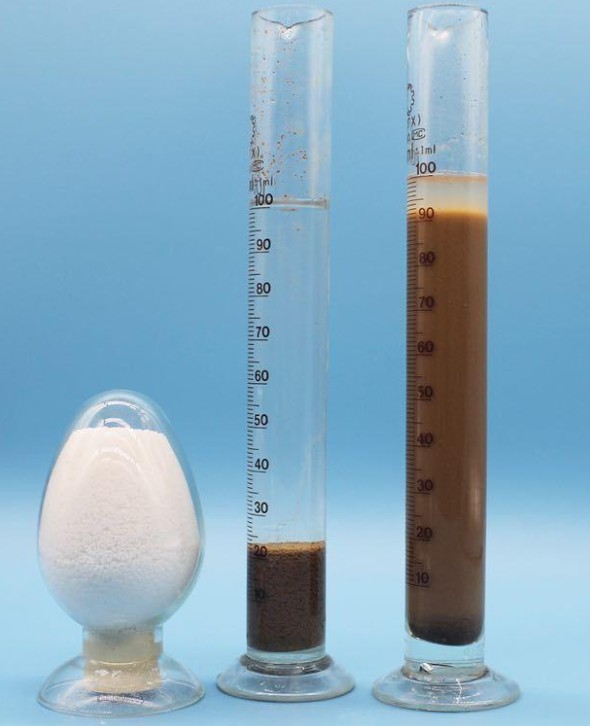

Many enterprises have taken many measures in the utilization rate of water resources, among which polyacrylamide is widely used as the most efficient and strong sewage treatment agent. However, many people will encounter some problems when using polyacrylamide as a sewage treatment agent for the first time – why is the water not flocculated as expected after adding polyacrylamide?

First of all, we know that polyacrylamide has a variety of forms, including anions, cations, nonions and zwitterions. The difference is that it has different effects on different sewage. When adding a certain amount of polyacrylamide does not achieve the desired effect, we first need to determine whether the reagent used is in line with the existing sewage treatment and dosage, and the most easily ignored Depending on the reaction of the agent.

1. To determine the pH value of sewage to be treated, anionic polyacrylamide is mainly used in weak acid to alkaline sewage treatment. If the pH value of water reaches strong acid, non-ionic polyacrylamide should be used for treatment. Generally, the pH value of sewage that can be treated by non-ionic polyacrylamide can be in the range of strong acid to medium alkali. Only in this way can better flocculation effect be exerted. When the pH value of sewage is not stable, we can also adjust the pH value to achieve a better treatment process. Wastewater with neutral water quality is easier to be treated than wastewater with alkaline and acidic water quality. This seemingly troublesome treatment method brings faster sludge separation reaction and cost reduction.

2. The usual way to select the dosage is to make a small test in the laboratory. Through repeated tests, the best dosage is selected. Then, in the field debugging, the experiment is taken as the result to adjust the scope according to the actual situation. The specific dosage is determined by the strength and size of sludge flocs and the situation of sludge outlet. Generally, the dosage of sewage sludge is determined by the strength and size of sludge flocs and the situation of sludge outlet When the sludge outlet enters the reservoir, the separation of flocs and water can be seen obviously, and the best state is not to produce wire drawing.

3. Flocculant reaction time, which is also the most easily ignored problem in many sewage treatment using polyacrylamide, thinks that as long as adding polyacrylamide can well obtain the separation of sludge and water, but often ignores the most important reaction time, we do a small test in the laboratory when adding quantitative polyacrylamide to fully integrate with sludge, using quantitative repeated shaking In practical application, when sewage and polyacrylamide are fused, sufficient flow rate and mixing time should be considered, so as to give full play to the appropriate effect of polyacrylamide.

Oubo Chemical is one of the biggest Polyacrylamide manufacturers in China, Oubo specializes in supplying Cationic Polyacrylamide, Anionic Polyacrylamide, and Nonionic Polyacrylamide, we have advanced equipment and professional staff, which ensure all the products and service to be in good order. The annual capacity of polyacrylamide has broken through 50,000 ions in 2018, and the quality management system of Oubo has been certified by IS09001:2008. We proudly stand behind our product.

Post time: Jan-21-2021